Low Cost High Efficiency BLDC

Client Requirements:

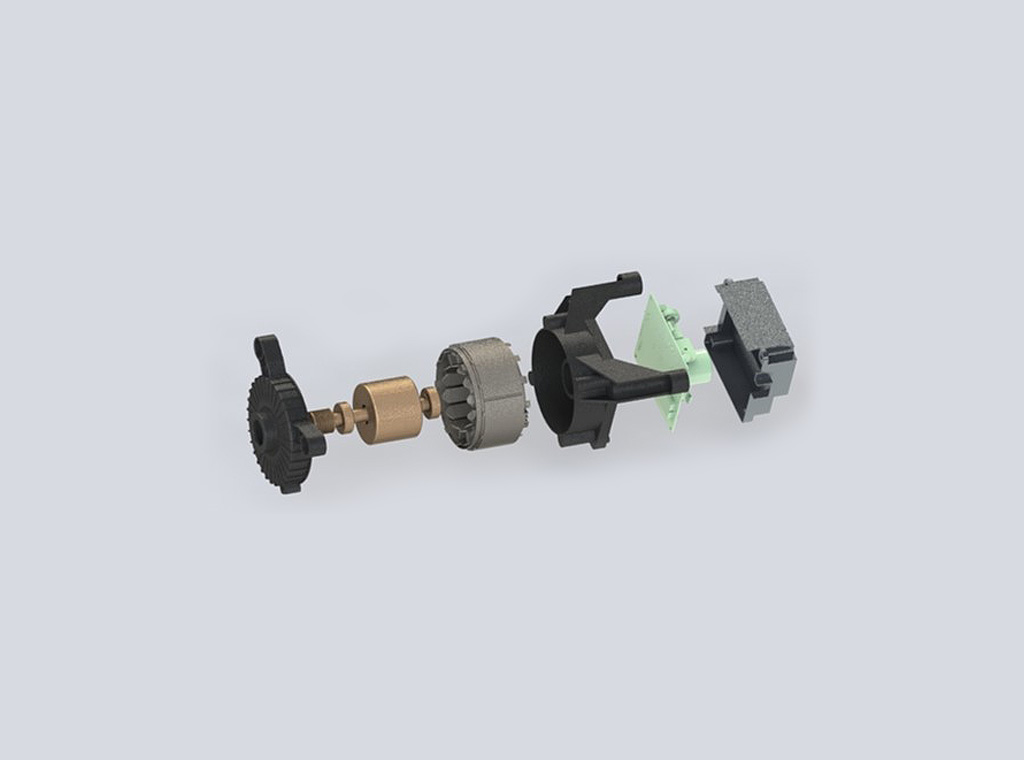

Migrate from Brushed DC to BLDC

Improved Efficiency

Extended Torque Speed Range

Low Cost

Project Summary:

Current winch technology is inefficient. Winches are designed using brushed permanent magnet DC motors, and the system efficiency can be as low as 15% with current draw as high as 320 amps at full rated load. Switching to a properly rated BLDC motor could greatly improve the performance of the winch within acceptable cost parameters.

Continuous Solutions utilized an in-house electric machine design optimization toolbox to develop an enhanced BLDC motor design based on the current brushed DC motor design. The design optimization toolbox is a combination of high fidelity magnetic equivalent circuit (MEC) -based machine models and genetic algorithm (GA) optimization, which allows rapid population-based optimization for complex design problems. This included rigorous system cost and savings analysis.